CNC Machining: Precision Manufacturing for the Fashionable Period

CNC Machining: Precision Manufacturing for the Fashionable Period

Blog Article

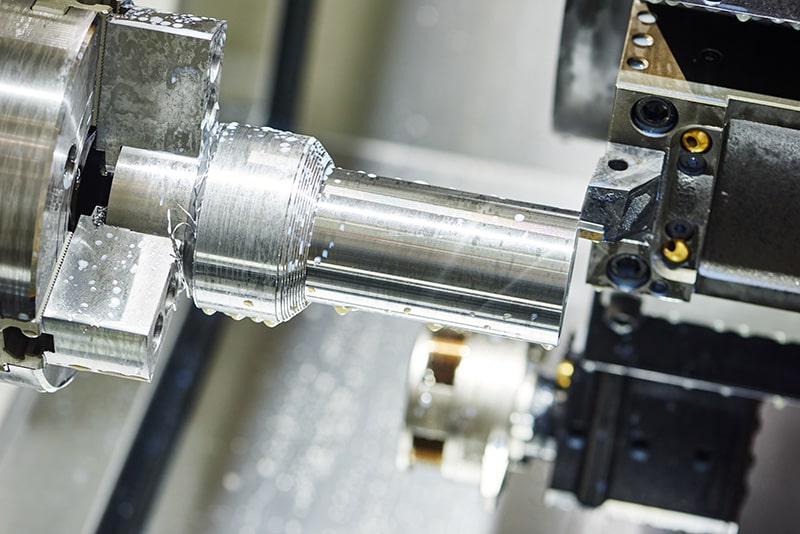

CNC machineries have revolutionized manufacturing industries, offering an efficient and precise process for making parts and components across a wide array of industries. The latest technology makes use of computer-controlled machinery to perform cutting drill, milling and various other processes on substances like metals, plastics, and wood. The precision that can be achieved with CNC machining is unparalleled which allows complex designs to be executed at a high level of accuracy. Through replacing manual input by automation, CNC machines have significantly decreased the chance of human error, and also increased productivity. The combination of precision with efficiency has helped make CNC machining a vital component of the modern manufacturing process.

One of the most significant benefits of CNC machining is its ability to fabricate intricate and complex parts that are extremely precise. Unlike manual machining, where precision is largely dependent on the skills of the operator CNC machines adhere to programmed guidelines with a high degree of precision. Digital instructions, typically created through CAD (Computer-Aided Design) software, allow producers to make parts with the precision of a couple of microns. The level of accuracy is vital in sectors such as medical device and aerospace manufacturing, where slight deviations can affect the performance or safety of a product. By using CNC machines, makers can ensure that every part is in compliance with the exact specifications, thus reducing the chance of defects, as well as the requirement for costly repair.

Efficiency is another significant benefit in CNC machining. After the design has been programed in the machine it runs automatically, performing multiple operations with no need for human intervention. Automation results in faster production time and more reliability in the product quality. Additionally, CNC machines can operate constantly, which means manufacturers can produce parts around every minute, thereby which can increase overall output. In contrast to traditional machines, which need highly skilled workers to operate the machines, CNC machining offers a considerable reduction in costs for labor and the risk of errors by humans, which makes it a cost-effective solution for manufacturing in high volumes.

Another key benefit of CNC machining is its efficiency. With the help of automation, machining manufacturing companies can drastically cut down the amount of time needed for the production of parts, leading to quicker production times and reduced costs. Because CNC machines operate all day long with no human oversight it is possible to increase production without compromising the quality. The level of automation minimizes the risk of human error, ensuring the quality of each piece produced is in line with all specifications set out in the digital layout. Additionally, CNC machining allows for "lights-out" manufacturing, where the machines can continue operating even after workers have left increasing productivity and cutting down on labor costs. To generate more details kindly head to www.premiumparts.com/services/cnc-machining

One of the problems with CNC machining is the initial set-up cost. Making investments in CNC machines and the software that is required for it could be costly, especially for smaller enterprises. However, the longer-term advantages of CNC processing, including lower labor costs, increased production effectiveness, and improved products' quality usually outweigh the cost of the initial investment. Furthermore, many businesses provide CNC machine-making services to companies that may not have the money to invest in their equipment, thus enabling smaller businesses to take advantage of the technology without the upfront costs. While the need for CNC manufacturing continues to grow as well, the expense of equipment as well as software is likely to decrease, making it more easily accessible to more of companies.

As a conclusion CNC is now an integral part of modern manufacturing owing to its precision performance, efficacy, and broad range of applications. It has transformed the way components are made, which allows for the creation of complex designs that have a high level of accuracy while reducing manufacturing costs and times. Although it is a significant initial investment but the advantages that will last for a long time CNC machining make it a beneficial tool for business across different fields. As technology evolves, CNC machining is likely to play an even more crucial role in shaping the manufacturing future, driving technological innovation while helping companies to meet the needs of an ever-changing global marketplace.